LINK RESOURCES Australian Heavy Industry Training & Personnel Services

Link Resources provides Heavy Industry training and personnel service across Australia to workers and organisations looking to fill a gap in their qualifications or services.

Our huge range of courses offer workers the chance to take their careers to the next level, with the option to personalise courses to any location, allowing easy access to our industry-leading trainers and resources. For organisations, Link Resources offers the best of the best in emergency response personnel and equipment, ensuring your workplace is safe and secure.

We are committed to being flexible, adaptive and client-focuses to work in partnership to achieve all your goals and deadlines.

TRAINING

Link Resources offers a wide range of courses to people in heavy industry. We offer companies and workers contextualised coursed and pride ourselves on ensuring students are not only competent but confident in applying the knowledge and skills in the workplace when they finish training with us.

Our personnel work tirelessly to be responsive and flexible in frequently offering a large scope of courses across many locations.

COURSES

Our highly experienced trainers couple with world class facilities and resources allow us to deliver the best training in industry. Enrol now to start developing your knowledge and skills.

CAREERS

Explore a large range of career paths in Heavy Industry that can be opened up with the guidance and competencies you gain through our courses

OUR BUSINESS SERVICES

Google Review

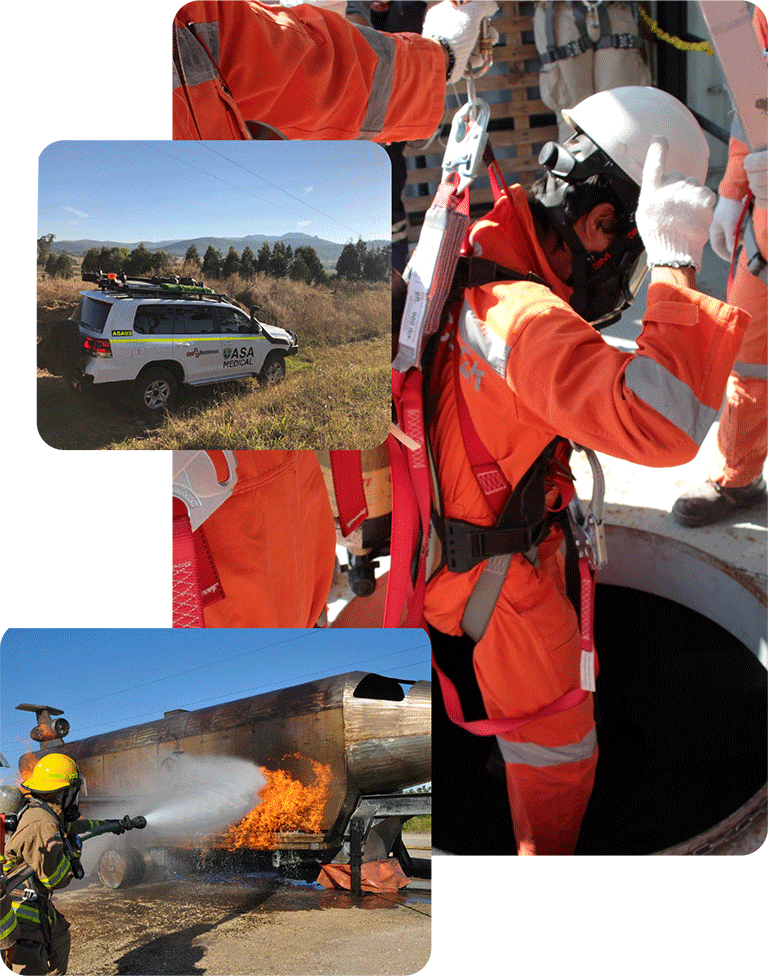

We can provide you with health and medical personnel such as nurses and paramedics, as well as ambulances and other onsite medical facilities.

HEALTH & MEDICAL

We can provide you with health and medical personnel such as nurses and paramedics, as well as ambulances and other onsite medical facilities.

FIRE & RESCUE

We can provide you with fire and rescue personnel such as firefighters and mine rescuers, as well as full fire and rescue fit out gear for your team.

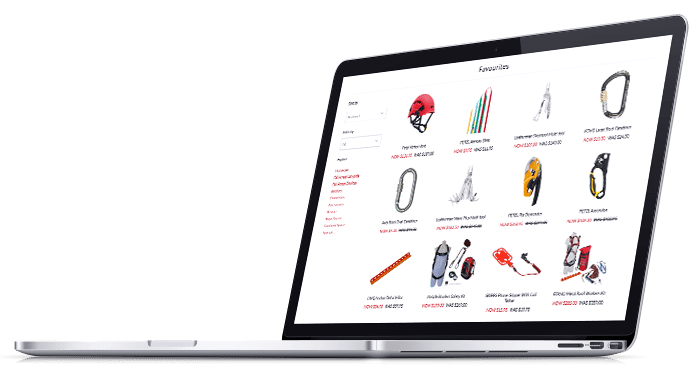

EQUIPMENT SUPPLY

We can supply you with specialist equipment such as height safety equipment and confined spaces equipment, so that your team can do their jobs safely and effectively.

CONSULTING SERVICES

We can consult with your business in areas such as health and safety, emergency preparedness, rehab & return to work, health & wellbeing and learning & development.